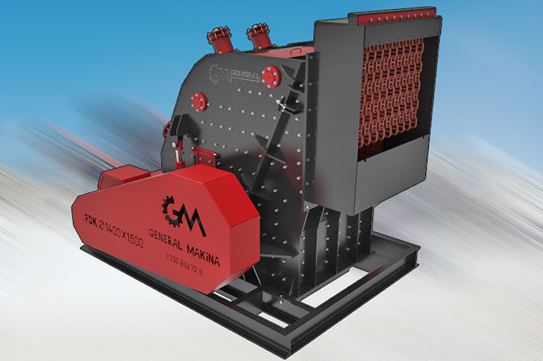

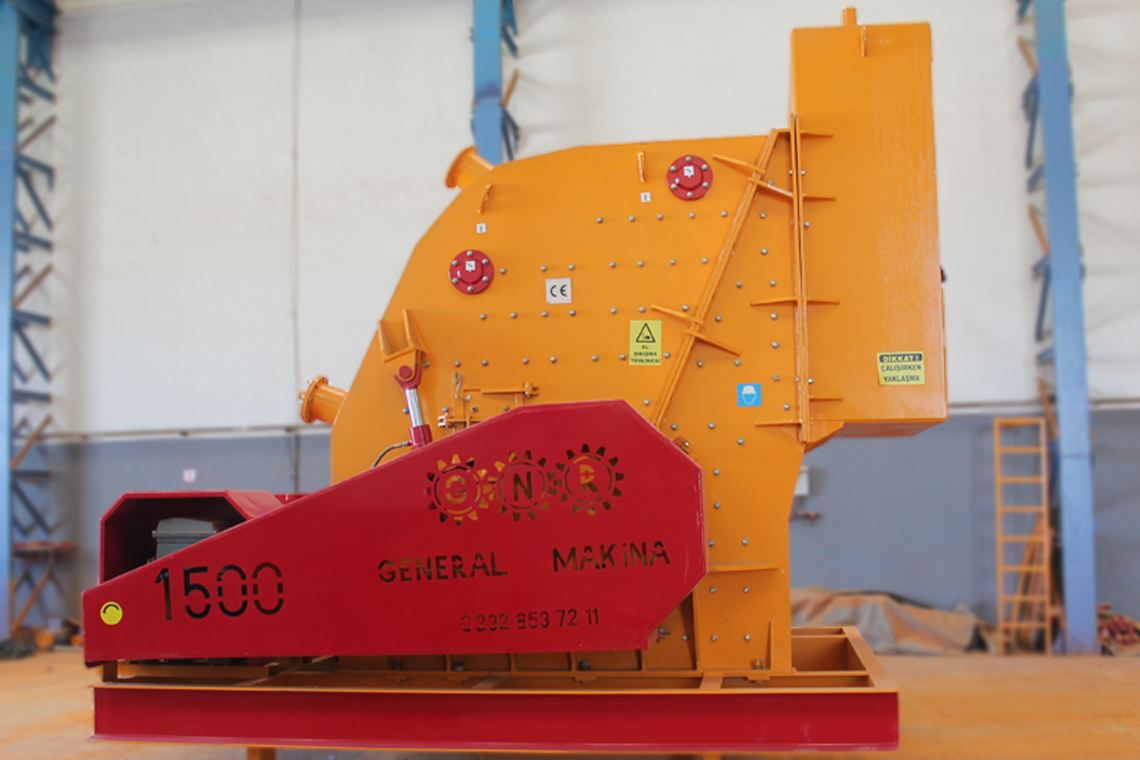

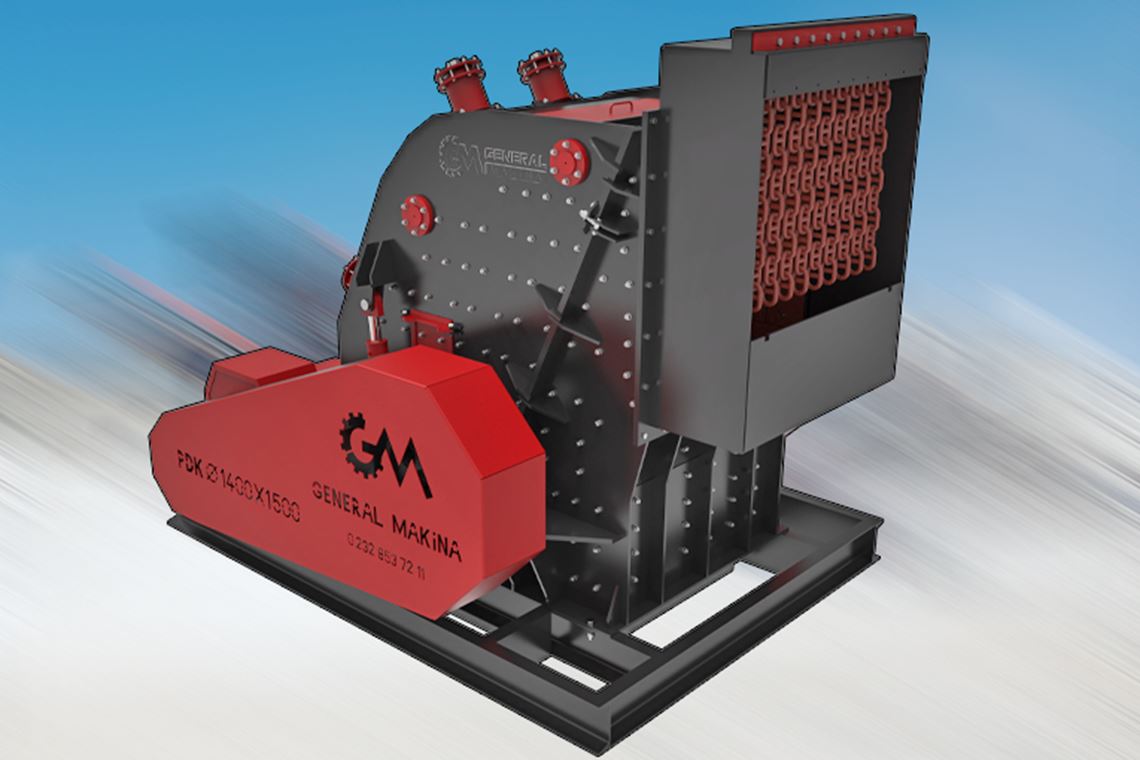

Primary Impact Crusher

Primary Impact Crusher 's general features:

- High capacity

- High reduction ratio

- Production of highly thin material

- Cubic material

- Ease of maintenance

GENERAL MACHINE Primary Impact Crushers, crush the stone medium hardness (with less abrasive) , as controlled, do the primary level. 1300 mm with a weight of 3000 kg of stone, it is possible to decrease the 0-100 mm with Primary Impact Crusher. Stone into the crusher, stone by stone before impact with the shock of the impact plates on the rotor's upper wing and then crushs into the strike plate on the lower wing. Crusher main body is in two parts, the upper part of the hydraulic crusher maintenance completely open with strike plate and cylinder liners palette tests are done easily possible to change.

Pendulum carrying crusher impact plates and rotor clearance between the screw-spring or hydraulic mechanism (optional) can easily be controlled by adjusting the size of the output product.

General Machinery Primary Impact Crushers are your best choice for crushing materials such as basalt, limestone, dolomite, granite. All our crushers has a guaranteed and we are manufacturing Primary Impact Crushers with ISO 9001 and CE certificates.

Turkish

Turkish English

English Russian

Russian French

French Spanish

Spanish Arabic

Arabic Serbian

Serbian