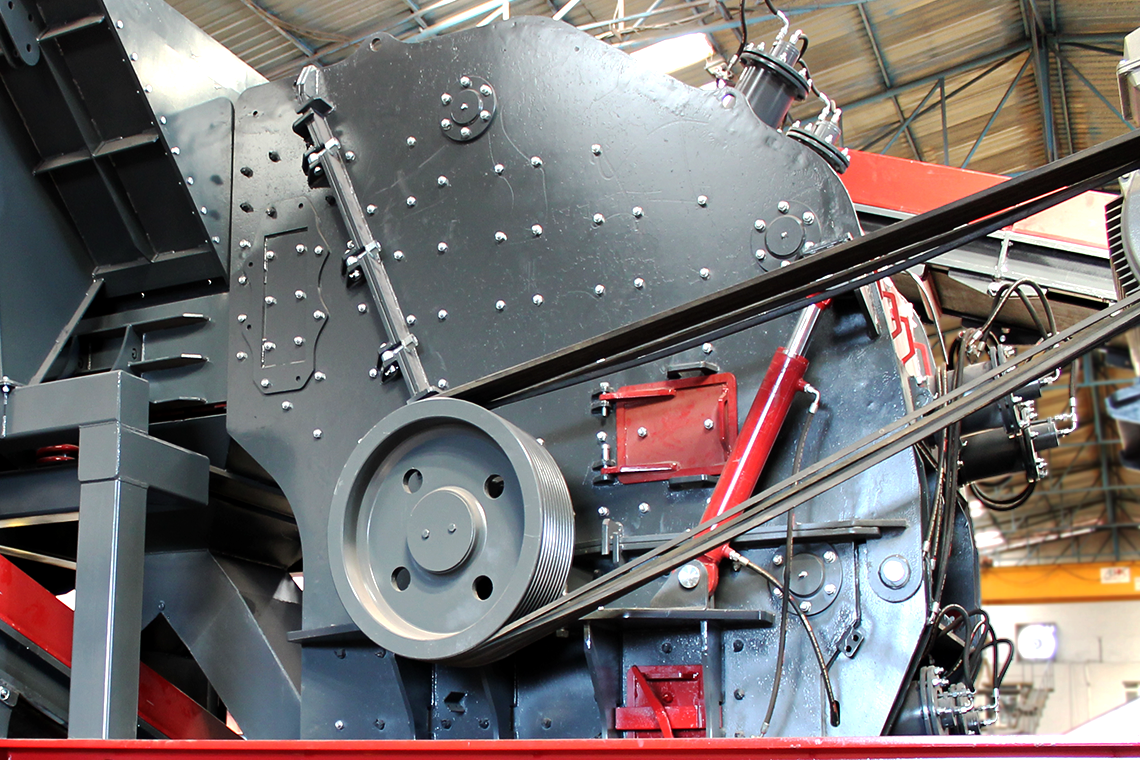

- 3-Chamber Turbo Crushing System

- Strong, Durable, and Heavy-Duty Main Body

- High Capacity and Maximum Efficiency

- Long Spare Part Life

- Ease of Operation and Tracking

GPS Series is the last series of professional stone-crushing machines that General Makina has developed in the last few years.

The basic element that makes the GPS Series Primary&Secondary is the triple pendulum system that enables it to perform the primary and secondary crushing function in a single machine, unlike a classical impact crusher.

This crusher has been created with the latest technology of General Makina, the leader of the stone-crushing industry for 50 years.

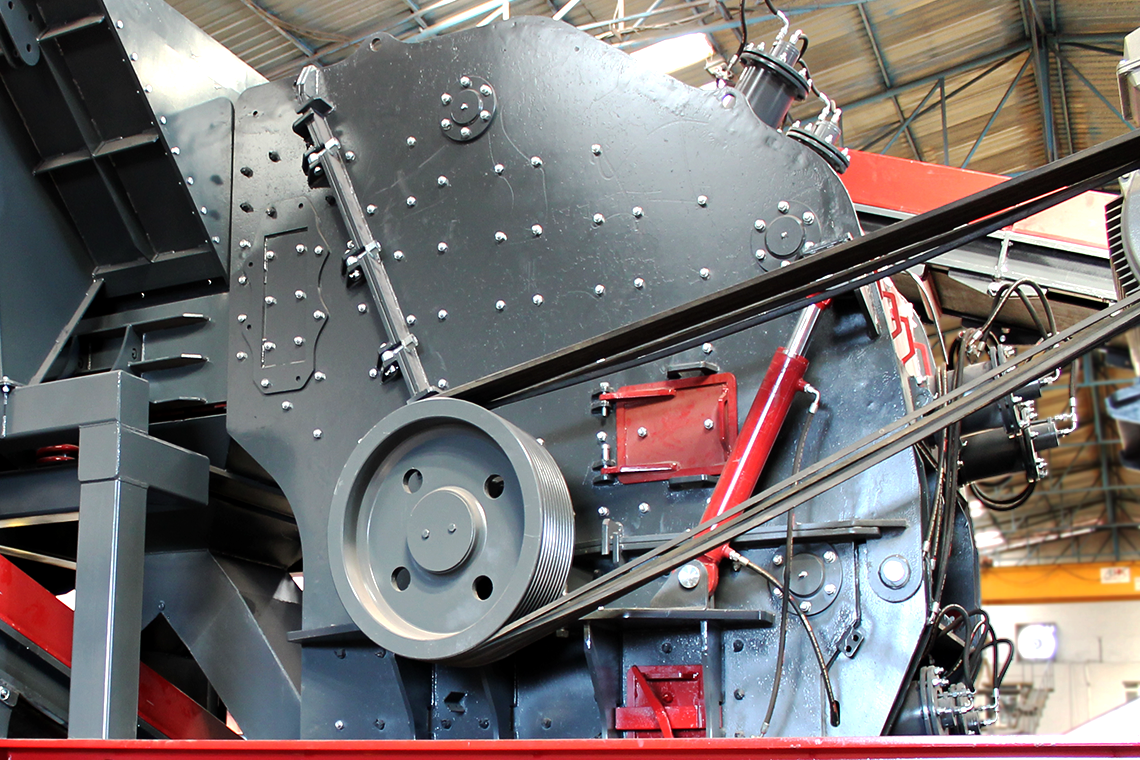

The GPS Series Impact Crusher's crucial role is to increase the capacity of stone crushing and screening plants or to increase the fine material ratio, the 3rd Pendulum unit is pulled back to increase the capacity with the unique triple pendulum system.

In order to increase the fine material ratio, the 3rd Pendulum unit is driven forward. The process is that simple, there is no need for an extra crusher or return conveyor belt.

It can be used in all fixed, mobile, or semi-mobile crushing and screening plants.

It crushes non-abrasive medium and soft stone and mineral materials with high efficiency.

In addition to the classical road, and dam construction works, it is used in a wide range of industries, including mobile recycling facilities.

GPS Series Impact Crushers are offered with a 2-year warranty, 24-hour technical support service domestically, and a maximum of 48-hour service internationally.

You can contact our professional sales team immediately for the price of the GPS Impact Crusher or other impact crushers.

TR

TR EN

EN RU

RU FR

FR ES

ES AR

AR SR

SR