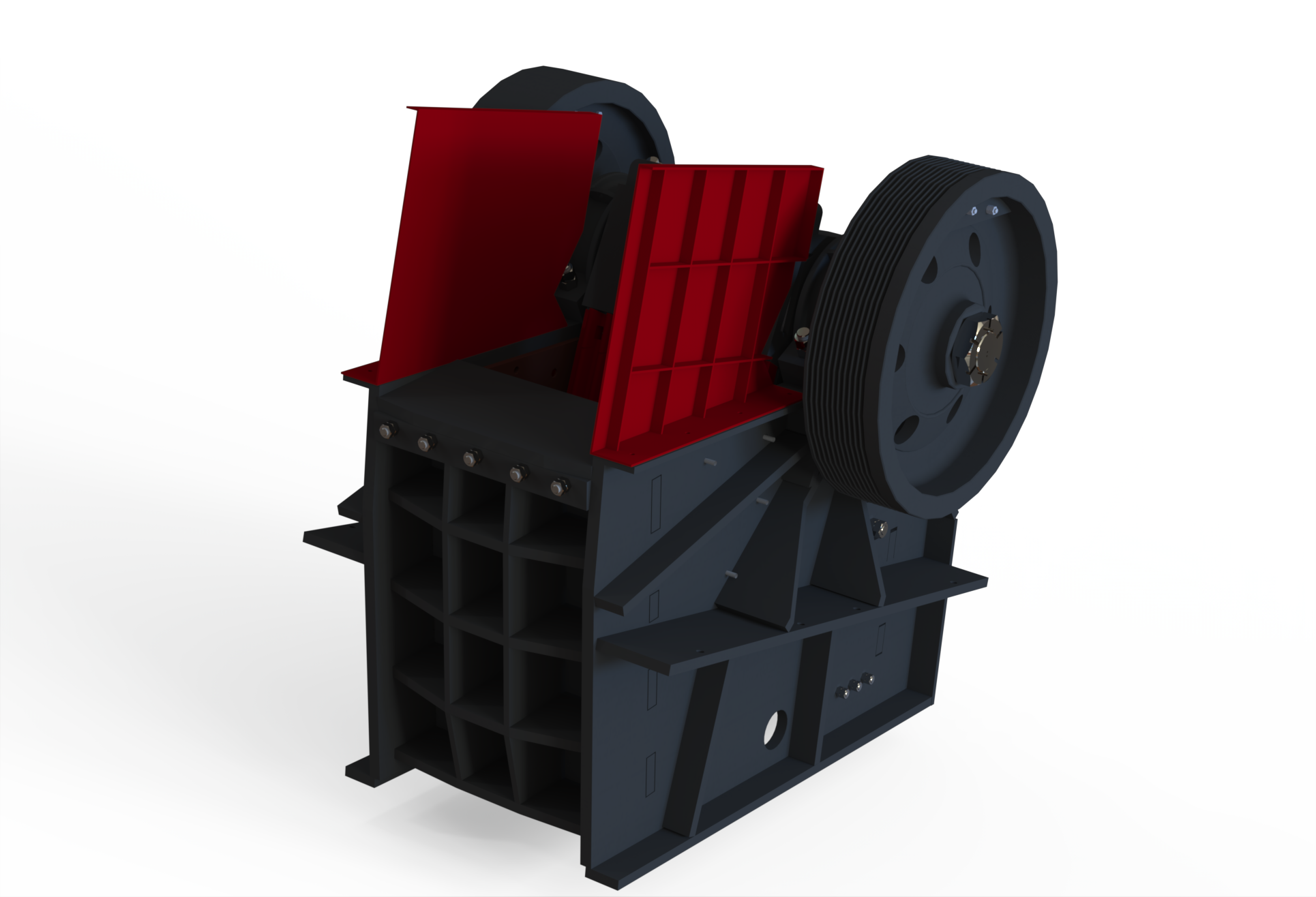

- Capable of Crushing All Rocks

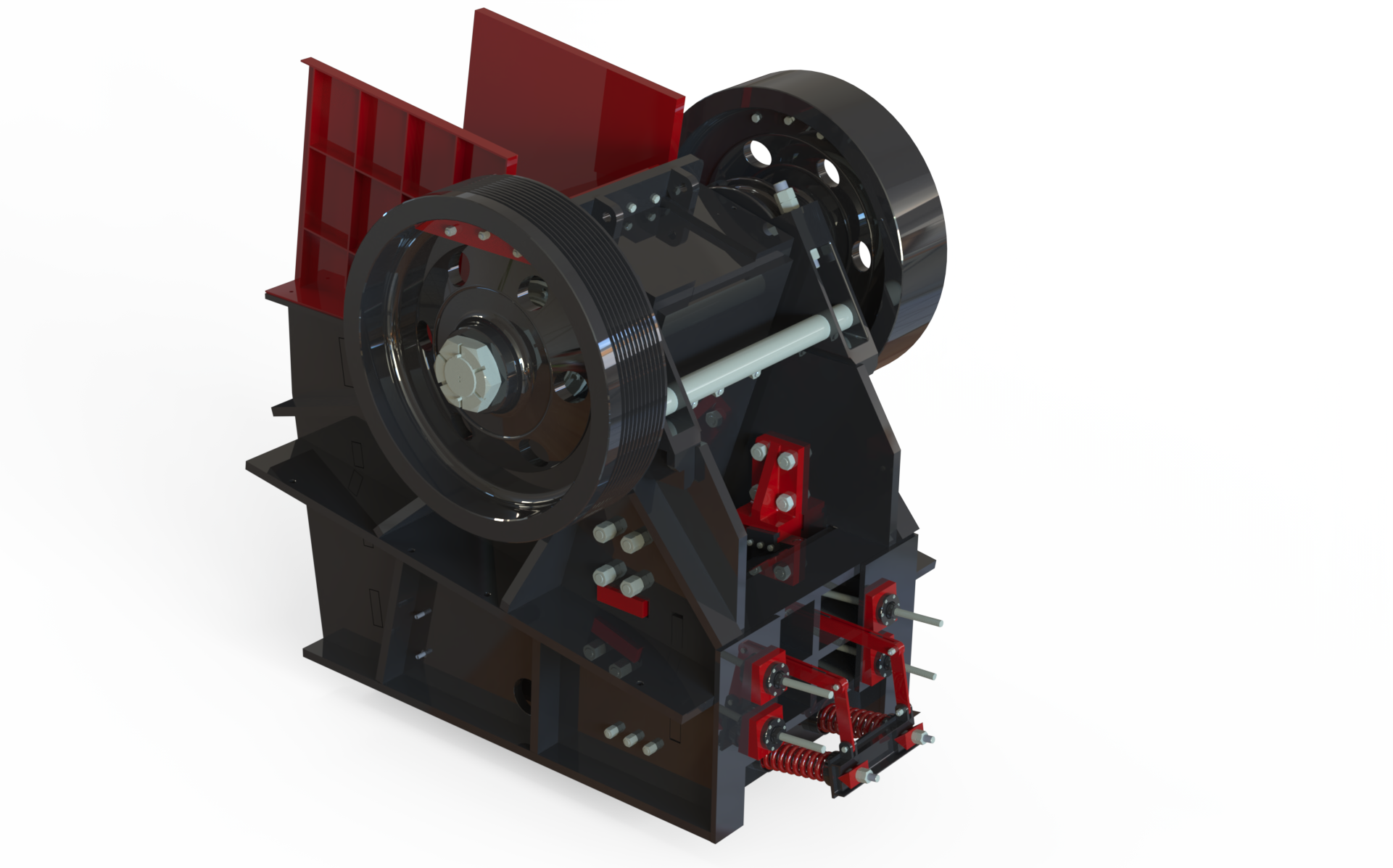

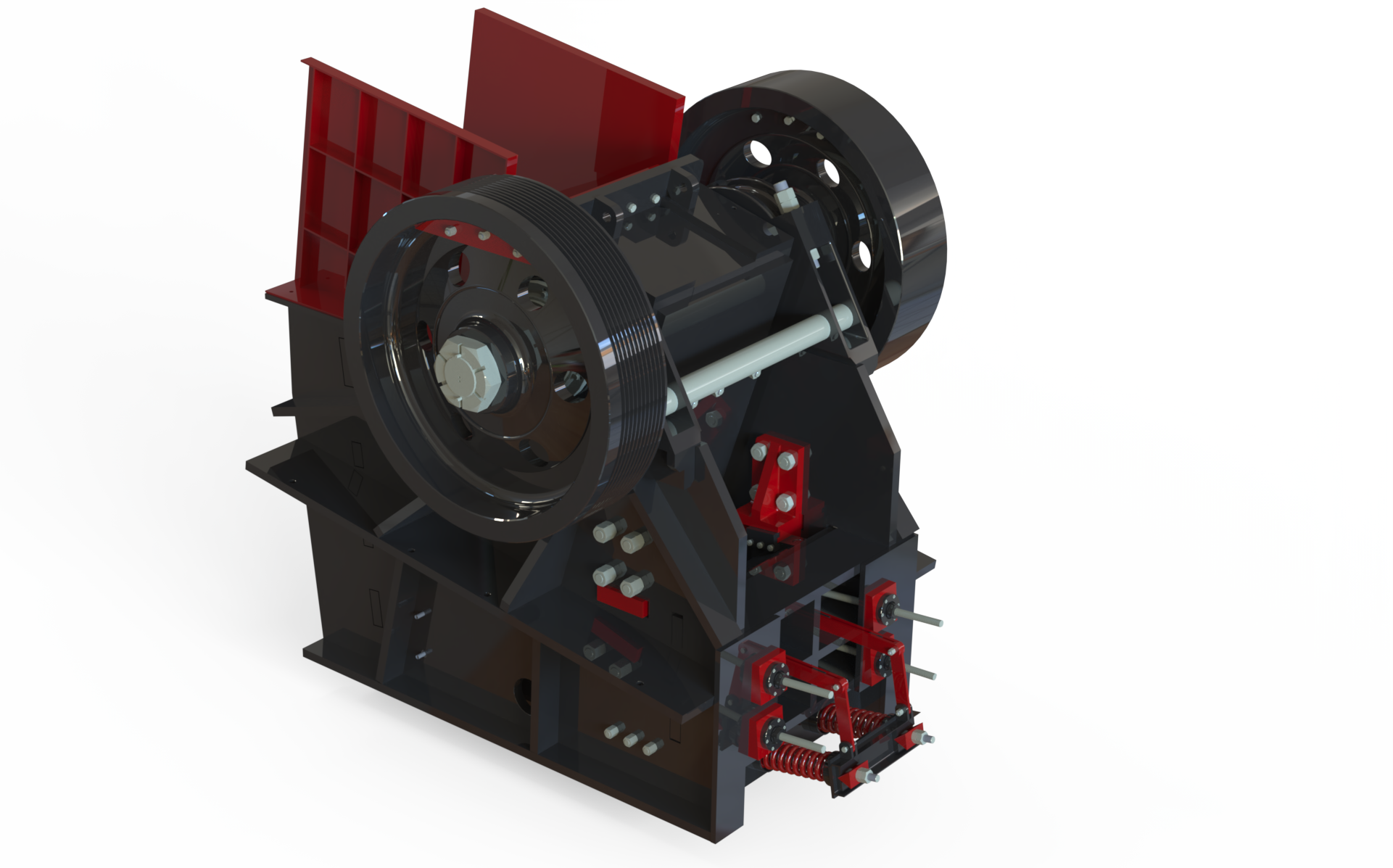

- Strong, Durable, and Heavy-Duty Main Body

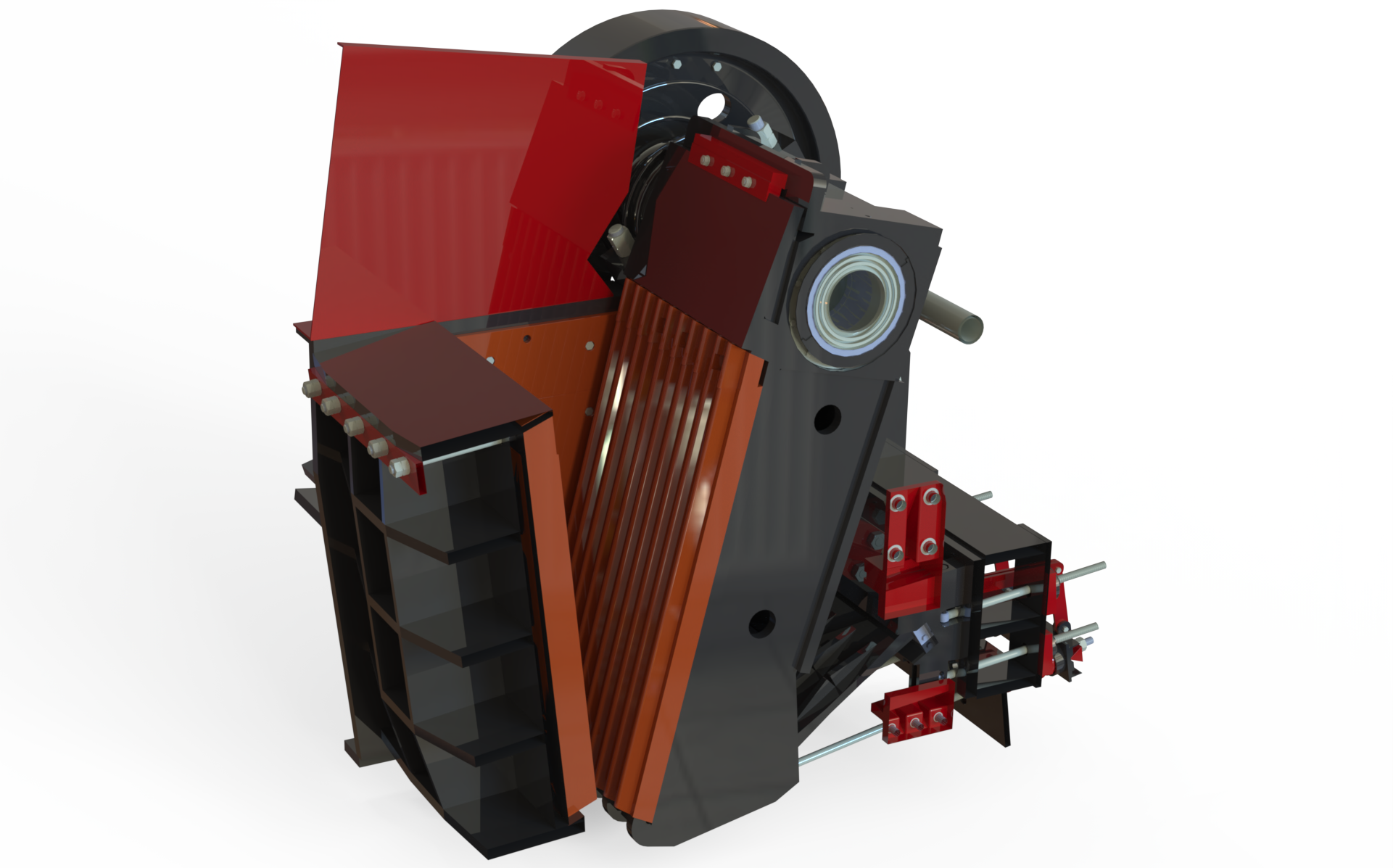

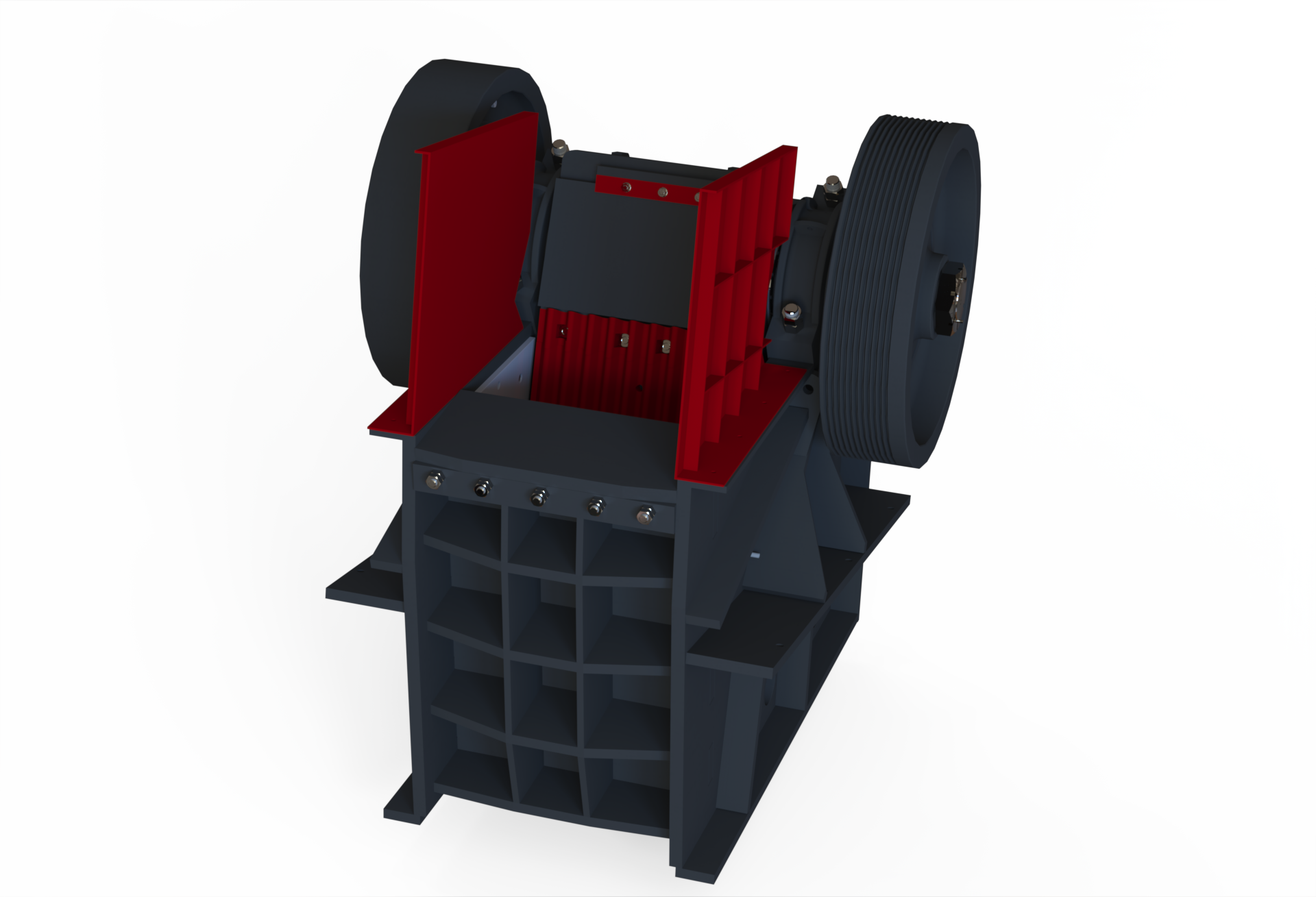

- High Capacity and Maximum Efficiency

- Long Spare Part Life

- Ease of Operation and Tracking

Even the hardest materials that can break easily with jaw crusher and its allows the jaw opening to be adjusted easily and quickly capacity according to the product, which you want to take product from machine with hydraulic systems. It also requests an automatic lubrication system which can be applied to this product, it line has been designed in order to give the result of its superior engineering services with work smoothly for you.

Generally It is impossible to acquire the desired material dimension through a single crusher. General Machinery Jaw Crusher can be used material as the primary crusher, used as a secondary crusher to refine the material too. It is narrower than the secondary jaw crusher feeding mouth opening of the primary crusher. When crusher selection ,material and product sizes and hourly production capacity are determining factors. Feeding space between the jaws should be selected larger than the maximum size of material to be fed. Thus, large stones can not create congestion in the mouth, capacity will be increase by continuous feed.

TR

TR EN

EN RU

RU FR

FR ES

ES AR

AR SR

SR